Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The sanitary TC ferrule check valve is a vital component designed to ensure the unidirectional flow of fluids in sanitary systems. It plays a crucial role in preventing backflow or reverse flow, safeguarding the integrity and efficiency of the system.

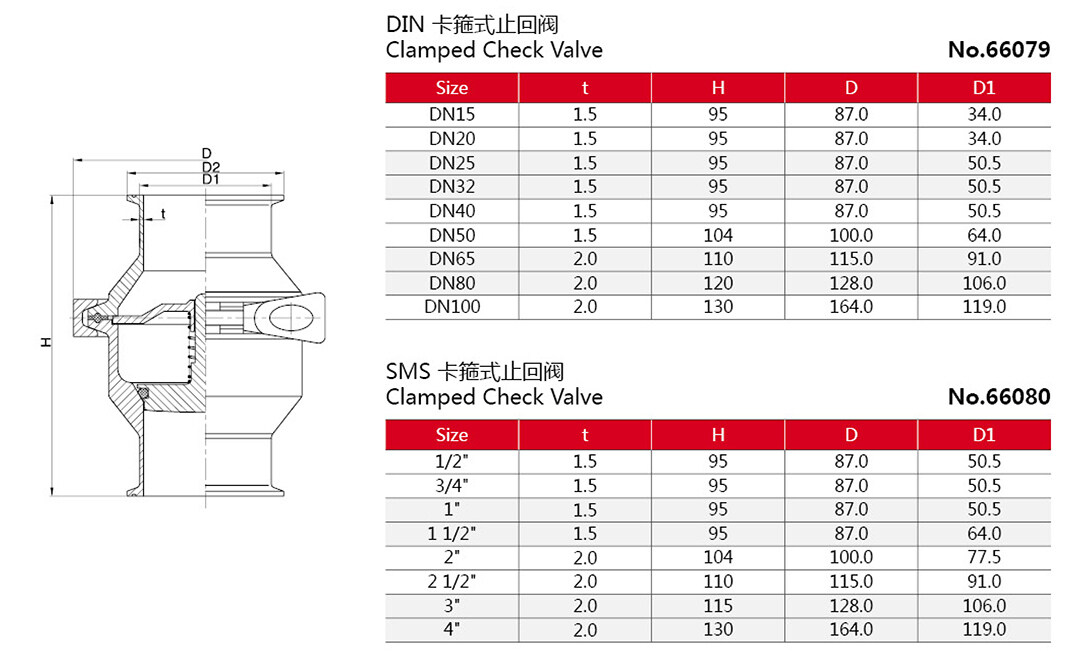

Product parameter

| Standard | SMS,DIN,3A | |

| Material Contact Parts | SS304/SS316L(1.4301/1.4404) | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Size | 1/2” to 12”,DN10 to DN300 | |

| Connection | Butt-weld,Tri-clamp,Male Thread,Female-Male Threaded,Union,Weld-Thread,Flange | |

| Seal Material | Silicone,EPDM,FKM,Buna.All seals material comply with FDA21CFR117.2600 | |

| Power Option | Manual Operation | |

| Working Pressure | ≤10bar(145psi) | |

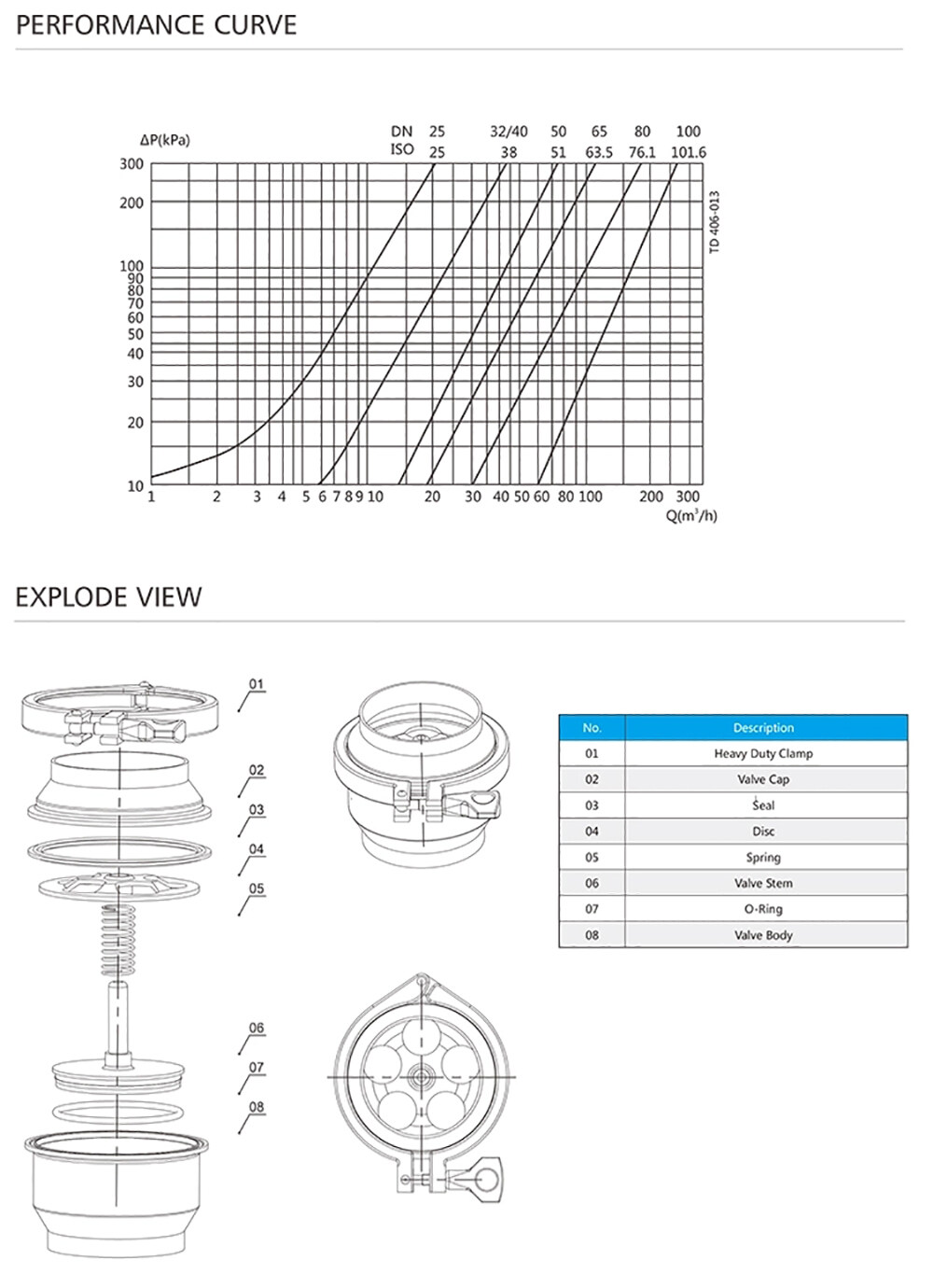

| Open Pressure | 0.3bar for DN25, 0.2bar for DN32/DN40, 0.1bar for DN50/DN100 | |

| Supply Pressure for Air Actuator | 5~8(72.52psi~116psi) | |

| External Surface Treatment | Ra32~64uin(0.8~1.6um) | |

| Internal Surface Treatment | Ra16~32uin(0.4~0.8um) | |

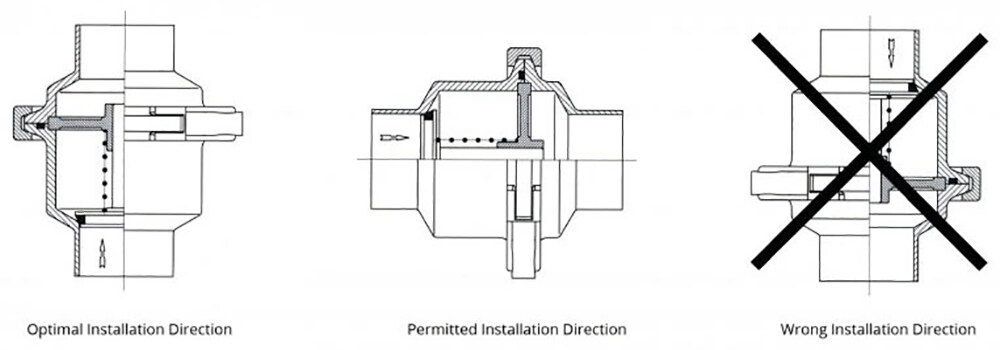

The sanitary TC ferrule check valve is specifically engineered for use in sanitary systems where backflow prevention is of utmost importance. It features a compact and streamlined design, allowing for efficient flow control and minimal pressure drop. The valve is designed to automatically open and close in response to fluid flow, ensuring reliable and uninterrupted operation.

Product drawing

Product Features

Application scenario

Product Advantages

1.Backflow Prevention: The Sanitary Check Valve effectively prevents backflow or reverse flow, ensuring the integrity and safety of the system and preventing potential contamination.

2.Equipment Protection: By preventing backflow, the check valve protects downstream equipment and components from potential damage caused by reverse flow, enhancing the longevity and reliability of the system.

3.Hygienic Fluid Transfer: The valve’s hygienic design ensures the cleanliness and integrity of the fluid being transported, making it suitable for sanitary applications in industries such as food and beverage, pharmaceuticals, and cosmetics.

Why Choose Us?

Expertise and Experience: We have extensive expertise and experience in the design and manufacturing of sanitary check valves. Our team of engineers and technicians are highly skilled and knowledgeable in the field, ensuring that our products meet the highest standards of quality and performance.

Quality Assurance: We are committed to delivering products of exceptional quality. Our sanitary check valves undergo rigorous testing and inspection throughout the manufacturing process to ensure they meet or exceed industry standards. We use only high-quality materials that are compliant with sanitary regulations, ensuring the integrity and cleanliness of the fluid being transported.