Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The sanitary air relief valve with pressure gauge is a crucial component designed to release excess air or gas from sanitary systems, ensuring the efficient and safe operation of the process.The Sanitary Air Relief Valve finds applications in various industries, including food and beverage, pharmaceuticals, biotechnology, and water treatment.

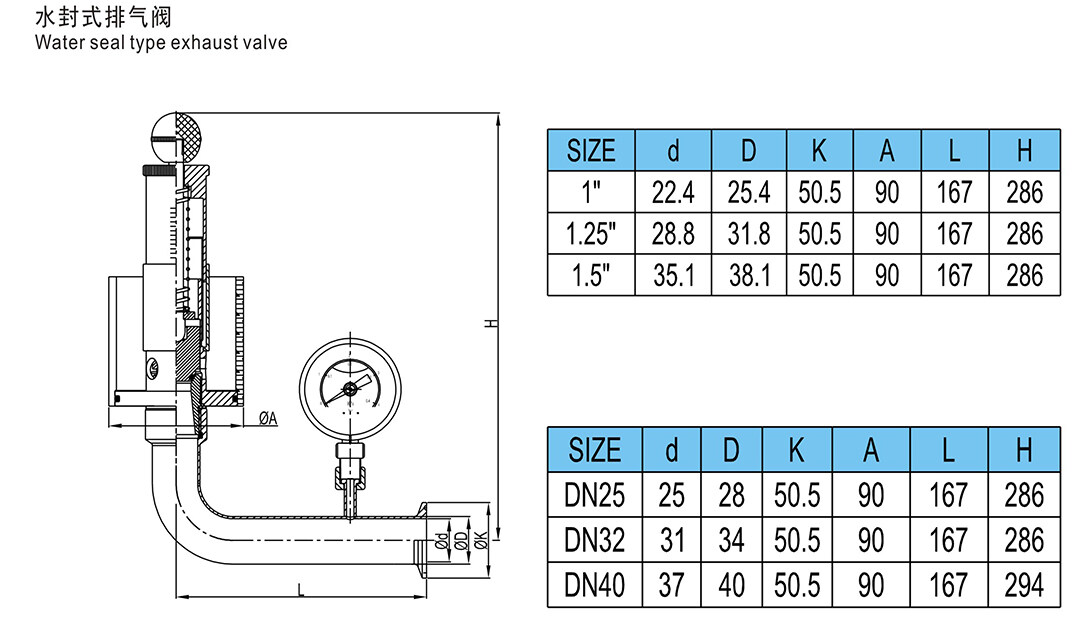

Product parameter

| Standard | SMS,DIN,3A | |

| Material Contact Parts | SS304(1.4301)/SS316L (1.4404) | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Size | 1” to 1.5”,DN25 to DN40 | |

| Connection | Butt-weld,Tri-clamp,Male Thread,Female-Male Threaded,Union,Weld-Thread,Flange | |

| Seal Material | Silicone,EPDM,FKM,Buna. All seals material comply with FDA21CFR117.2600 | |

| Media | Gas | |

| Power Option | Manual | |

| Pressure Range | 0.2~2.2bar(2.9~31.9psi) | |

| External Surface Treatment | Ra32~64uin(o.8~1.6um) | |

| Internal Surface Treatment | Ra16~32uin(0.4~0.8um) | |

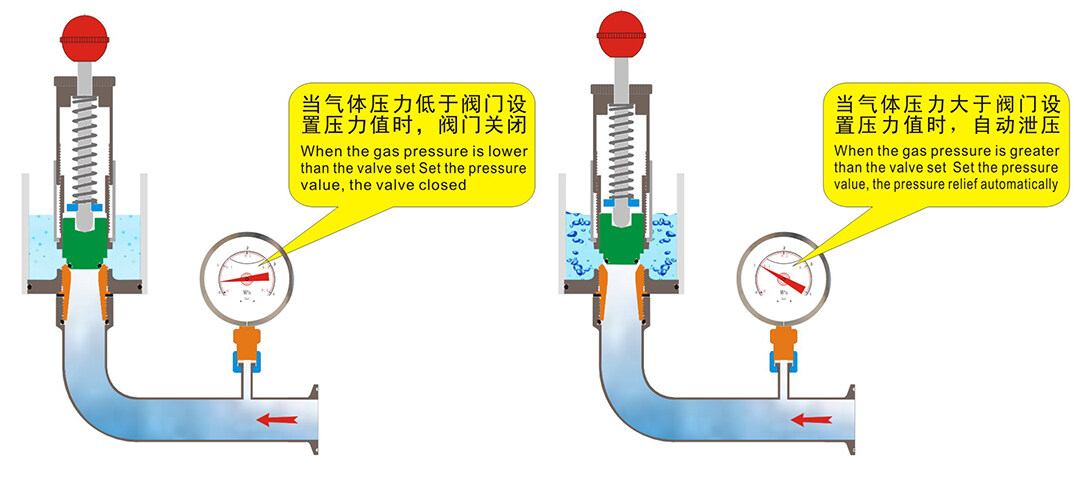

The sanitary air relief valve with pressure gauge is specifically engineered for use in sanitary applications where the removal of air or gas is essential. It is designed to automatically release trapped air or gas from the system, preventing issues such as air locks, cavitation, or reduced system efficiency. The valve is constructed with high-quality materials that meet sanitary standards, ensuring the cleanliness and purity of the process.It is suitable for any sanitary system where the removal of air or gas is necessary.

Product drawing

Product Features

Application scenario

Product Advantages

1.Energy Efficiency: The presence of trapped air or gas in a system can lead to decreased energy efficiency. The Sanitary Air Relief Valve ensures optimal system performance by removing air or gas, allowing for more efficient operation and potentially reducing energy consumption.

2.Process Optimization: The valve enables better process optimization by maintaining consistent pressure levels within the system. This helps to ensure that processes run smoothly and efficiently, minimizing variations and improving overall productivity.

3.Enhanced System Flexibility: The adjustable pressure setting feature of the valve allows for flexibility in adapting to different system requirements. This enables you to fine-tune the air release process according to specific operational needs, ensuring optimal system performance and adaptability.

4.Quick Response Time: The valve with pressure gauge offers a quick response time in releasing trapped air or gas from the system. This rapid response helps prevent potential disruptions or system inefficiencies, ensuring continuous and reliable operation.