Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Sanitary welded stainless steel tubes are meticulously crafted tubes that are specifically designed for hygienic applications. These tubes are manufactured with high-quality materials and undergo stringent quality control measures to ensure a smooth and seamless construction. The absence of weld seams eliminates the risk of bacteria or impurities getting trapped, making them ideal for industries such as food processing, pharmaceuticals, and biotechnology.

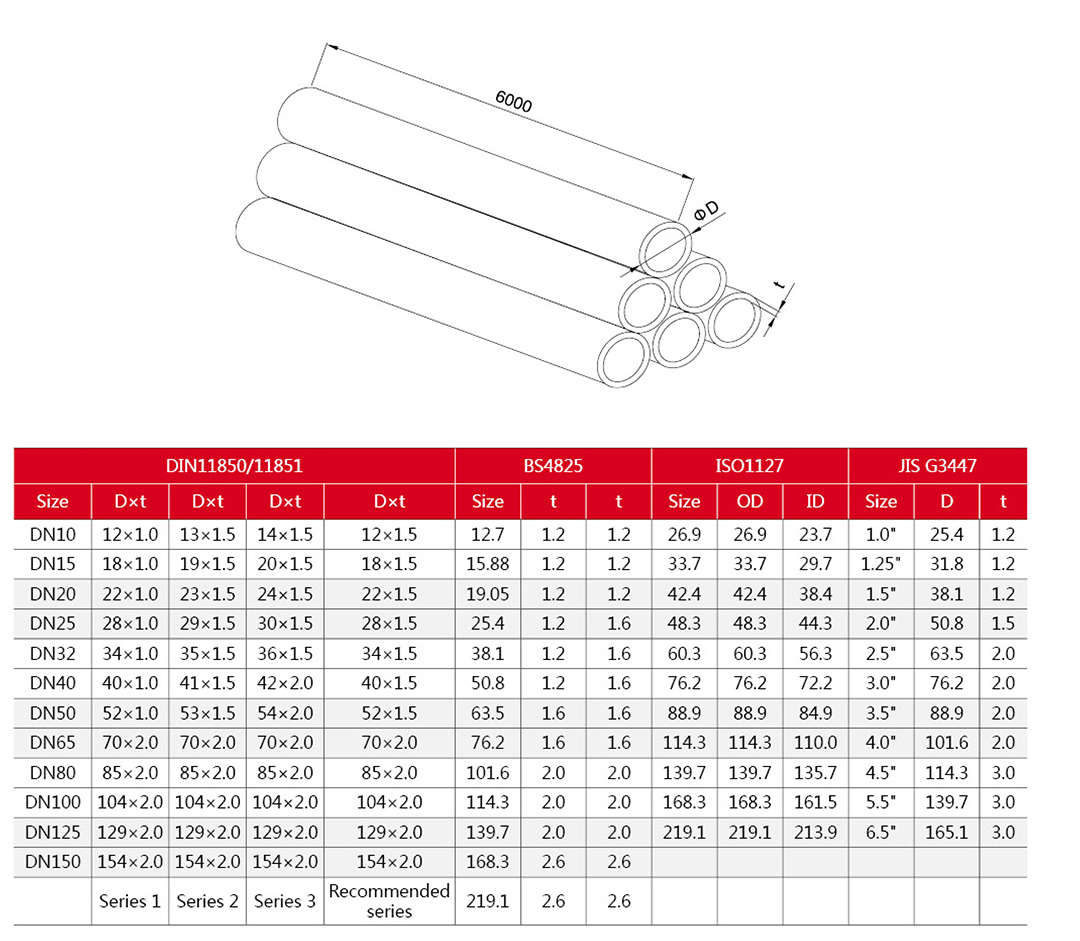

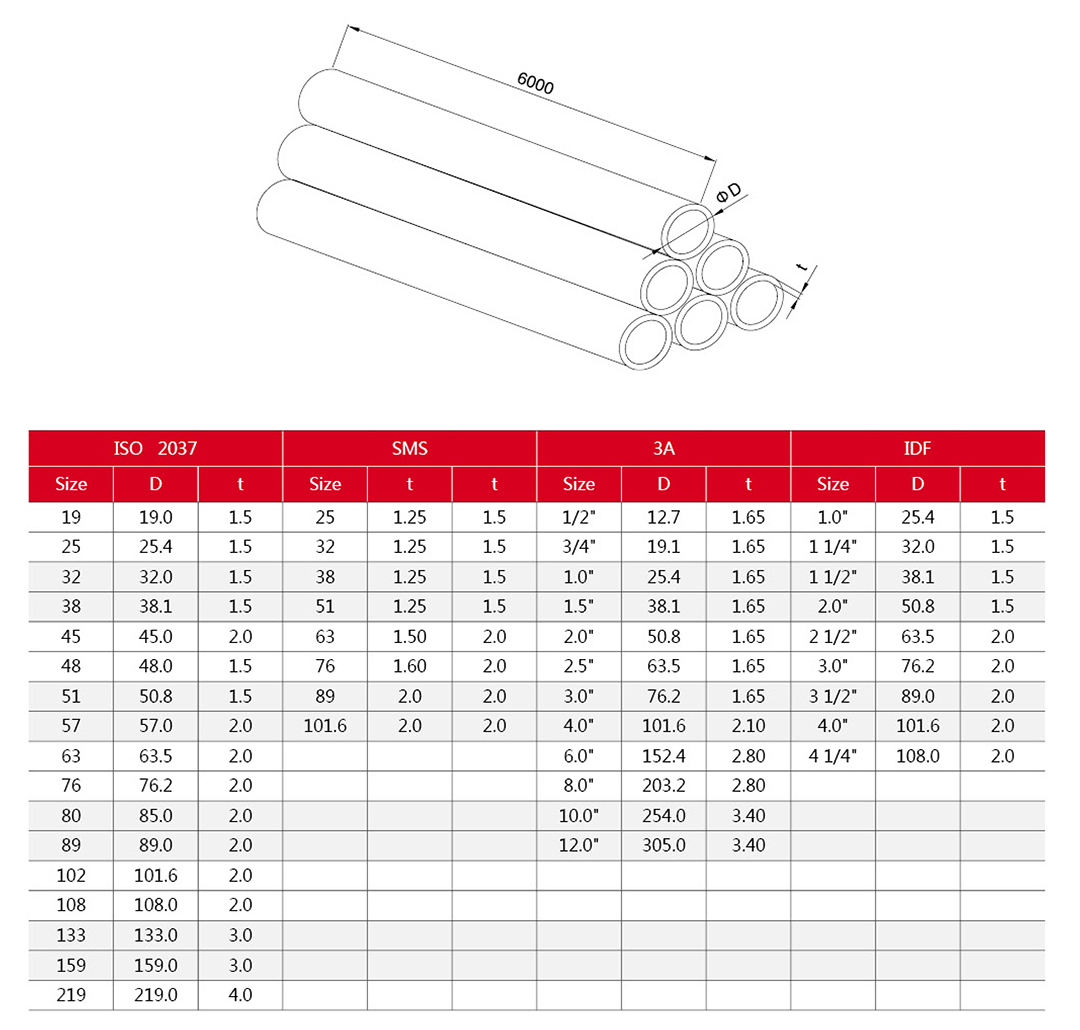

| Product Name: | Sanitary Welded Stainless Steel Tube |

| Material: | SS304 / SS316L / 1.4301 / 1.4404 |

| Production Standards: | ASTM A270 , AS 1528.1 , EN 10357 , DIN 11850 ,ISO 2037 , JIS G3447, KS D 3585 and so on. |

| Outer Diameter: | 6mm - 2000mm ; |

| Thickness: | 0.8mm - 20 mm ; |

| Length: | 6 Meters - 18.3 Meters ; As customers' request |

| Tolerance: | According to the Standard , +/-10% Commonly ; |

| Test: | Flaring test ; Flattening test ; Bending Test ; Hydraulic Test ; Eddy Current test |

| Surface Treatment: | Mirror polishing/matt polishing |

| Certificate: | ISO9001 |

Smooth Internal Surface Is Easy to Clean and Sterilize: Sanitary weld tubes feature a meticulously polished internal surface that ensures the prevention of contaminants buildup and facilitates effortless cleaning and sterilization. The smooth and polished finish of these tubes enhances their hygienic properties, making them an ideal choice for industries that require strict cleanliness standards, such as food and beverage processing, pharmaceuticals, and biotechnology.

Excellent Precision Welding Ensures Strong Connection: Welded stainless tubes are meticulously welded using advanced techniques like TIG welding, guaranteeing a robust and leak-proof connection. The welds are carefully executed to be flush or slightly recessed, facilitating effortless cleaning and maintenance. This meticulous welding process ensures the integrity and reliability of the tubes.

Good High-Pressure Capability Makes Various Application: Sanitary weld tubes are engineered to withstand high-pressure applications, catering to a diverse range of process requirements. Their ability to endure extreme pressures is determined by factors

such as the thickness and material grade used in their construction.

Product drawing

Standard Compliance: Sanitary weld tubes are meticulously manufactured to meet stringent industry standards, including ASTM A270 and 3A, guaranteeing compliance with rigorous sanitary requirements. These tubes undergo rigorous quality control measures to ensure their adherence to these standards, ensuring the highest level of hygiene and safety.

High-Grade Stainless Steel Ensure Optimal Corrosion Resistance and Durability: The tubes are meticulously crafted from premium stainless steel, predominantly 304 or 316L grades, renowned for their exceptional corrosion resistance and durability. These high-grade materials ensure the tubes can withstand harsh environments and corrosive substances, making them ideal for industries that demand long-lasting performance and reliability.

Various Sizes and Length Make Flexible Installation: Sanitary welded stainless tubes offer a diverse selection of sizes and lengths, providing unparalleled flexibility in design and installation. With a wide range of options available, these tubes can be tailored to meet specific project requirements, ensuring seamless integration into existing systems.