Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The high efficient, high shear dispersing emulsifier homogenizer mixer leverages advanced technology and innovative features to guarantee a precise and uniform blending process, resulting in superior quality emulsions. Its unparalleled efficiency and performance make it the ideal choice for industries seeking the highest standards in product formulation and development.

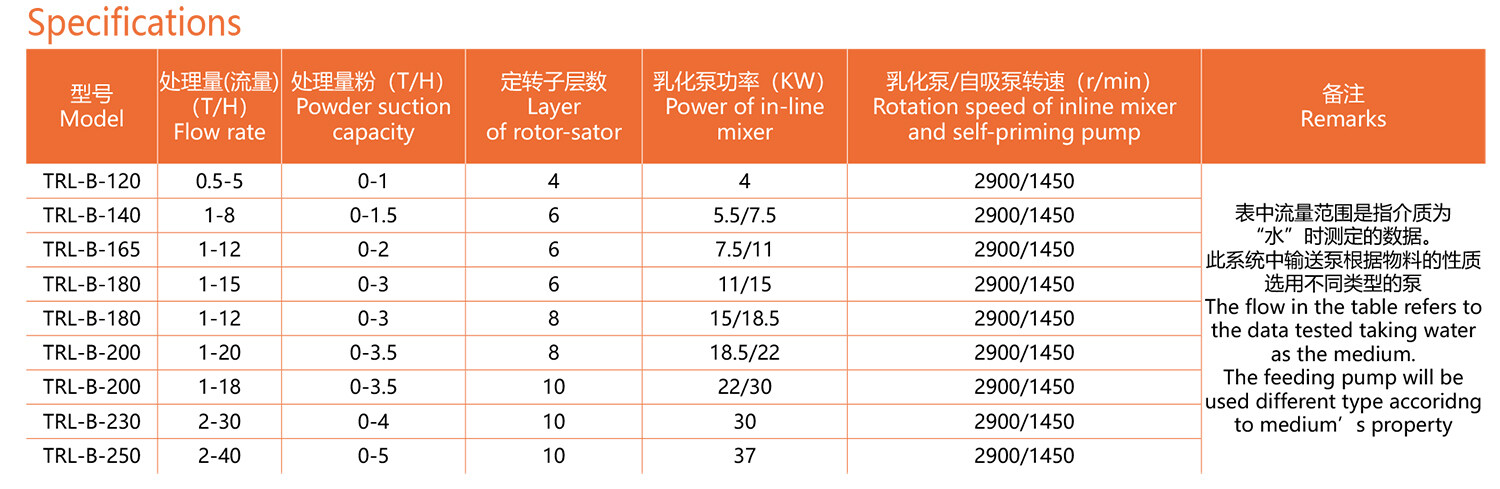

Product parameter

| Commodity | TRL-B High Efficient Online Mixer System | |

| Material Contact Parts | SS304(1.4301)/SS316L (1.4404) | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Stator Rotor Material | SS304(1.4301)/SS316L (1.4404) | |

| Sealing Material | EPDM,Silicone,FKM,PTFE. All material comply with FDA21CFR117.2600 | |

| Flow Rate | 0.5-40m³/h | |

| Maximum Flow Rate | 40m³/h | |

| Powder Suction Flow Rate | 0-5m³/h | |

| Layer of Stator Rotor | 5-10 | |

| Power of In-line Mixer | 4-37kw | |

| Rotation Speed of Inline Mixer | 2900/3500/1450rpm (Homogeneous Pump) | |

| Rotation Speed of Self-priming Pump | 2900/3500/1450rpm (Self-priming Pump or Rotary Lobe Pump) | |

| Voltage | 220v, 380v, 415v, ect | |

| Hertz | 50hz, 60hz | |

| Motor Brand | China Motor, ABB , Siemens | |

| Max. Pressure | 10bar (145psi) | |

| Maximum Temperature | 130℃/266°F (30min CIP/SIP) | |

| Connection | Butt-weld, Tri-clamp, Union, Thread, Flange | |

| Applicatio | Food Industry, Dairy, Homogeneous Mixed Milk Products, Biological Pharmaceutical Industry, Cosmetics Industry, Chemical industry, Homogeneous production of PVC plasticizers, Petrochemical Industry | |

| Max. Viscosity | 90000mPas | |

| Customized Support | OEM, ODM | |

The high efficient emulsifier homogenizer mixer pump is specially designed to efficiently mix and homogenize various substances. This advanced system greatly enhances the emulsification process, ensuring a stable and uniform mixture every time. With its powerful capabilities, it is ideal for industries such as food processing, pharmaceuticals, and cosmetics. The system's high efficiency enables faster and more precise mixing, saving valuable time and resources.

Product drawing

Product Features

Application scenario

Product Advantages

1.Easy to Maintain and Clean: The homogenizer emulsifier mixer is meticulously engineered to prioritize ease of maintenance and cleaning, thereby minimizing downtime and upholding impeccable hygienic processing conditions. This feature is of paramount importance in industries that adhere to stringent sanitation standards, such as the esteemed food and pharmaceutical sectors.

2.Greatly Increase Product Stability: The high shear dispersing emulsifier homogenizer mixer harnesses the immense power of high shear forces to effectively stabilize emulsions, suspensions, and dispersions. By preventing phase separation, this advanced technology guarantees products with an extended shelf life, ensuring their integrity and quality are preserved for longer durations.

3.Customizable and Flexible to Meet Specific Needs: The emulsifier homogenizer mixer system offers unparalleled customization options, empowering manufacturers to tailor it precisely to their unique processing requirements. This exceptional flexibility enhances product development and manufacturing capabilities, accommodating diverse batch sizes and formulations with ease.