Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The stainless steel self priming pump is a highly efficient and versatile pumping solution designed specifically for Clean-in-Place (CIP) processes in hygienic industries. This pump is engineered to provide exceptional performance, ease of use, and reliability during cleaning and sterilization operations.

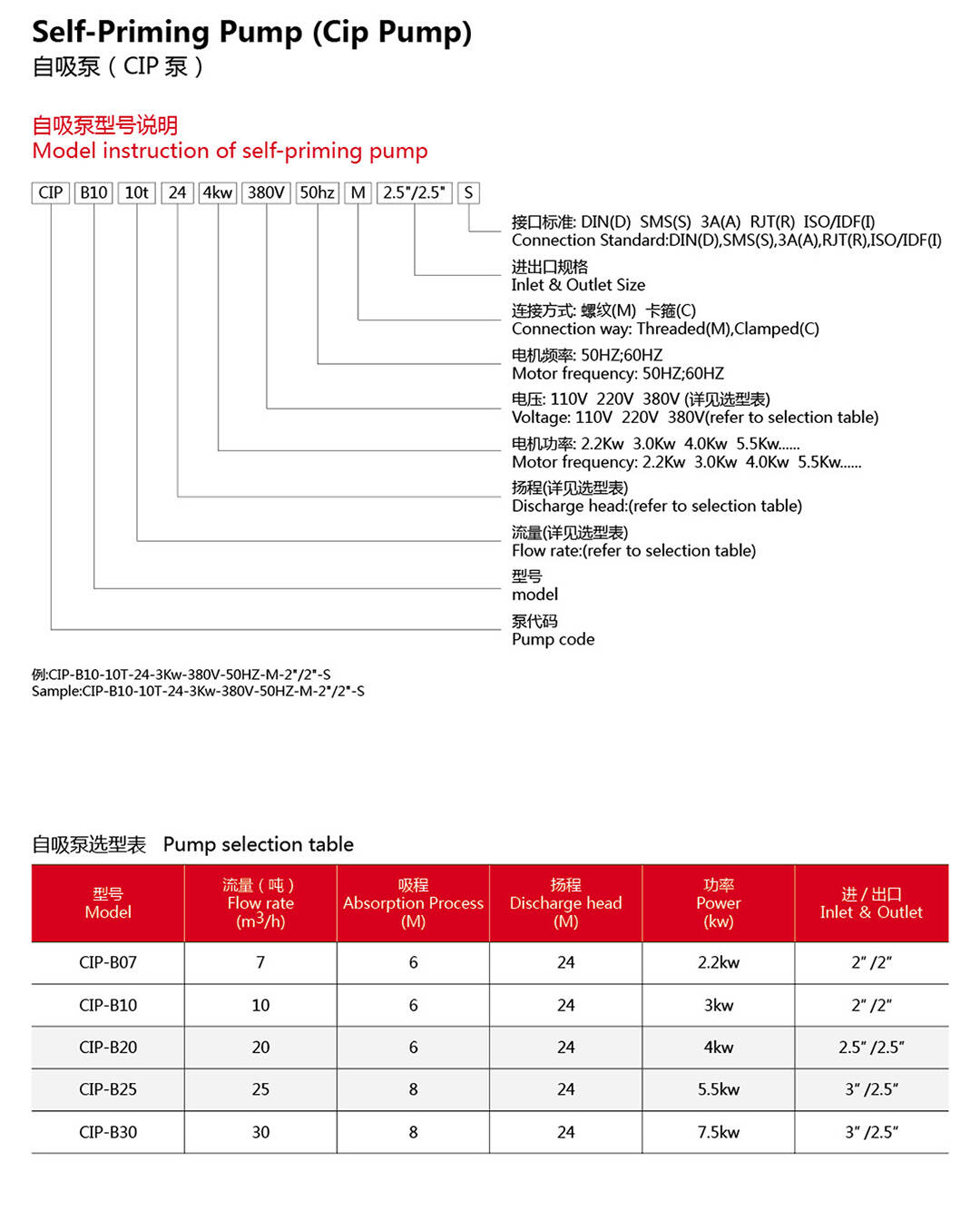

Product parameter

| Product Name: | Sanitary Self Priming Pump |

| Material: | SS316L |

| Seal Gasket: | EPDM FPM(Viton) and NBR |

| Max. Flow: | 30 m3/h |

| Max. Speed: | 1750 min |

| Max. Head: | 40M (4bar) |

| Temperature | -20~140 °C(-4~284°F) |

| Motor power: | 1.5kw~22kw |

| Mechanical seal: | SIC/C/EPDM (Standard), C/SIC, TC/TC |

| Voltage: | 110V, 220V, 380V |

| Motor: | ABB/SIEMENS |

| Motor Frequency: | 50HZ, 60HZ |

| Available connection: | Clamped, Threaded, Flanged |

Our sanitary CIP self priming pump is specifically designed to meet the demanding requirements of hygienic industries. It is an essential component in CIP processes, ensuring efficient and thorough cleaning and sterilization of equipment and pipelines. This stainless steel self priming pump is widely used in industries such as food and beverage, pharmaceutical, and dairy, where maintaining sanitary conditions and product integrity are paramount.

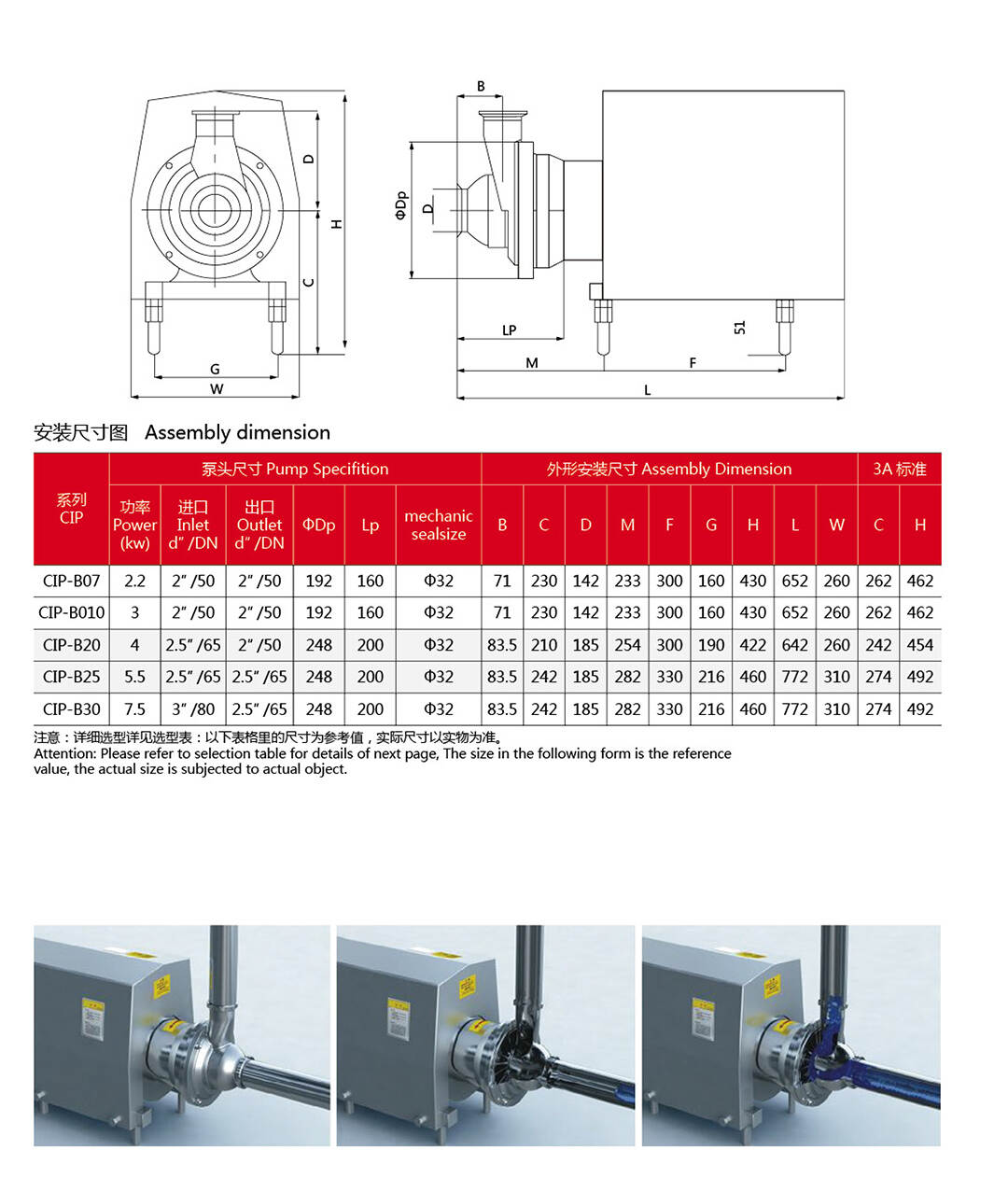

Product drawing

Product Features

Product Advantages

1.Efficient and Thorough CIP Processes: The sanitary CIP self priming pump ensures efficient and thorough cleaning and sterilization of equipment and pipelines. Its self-priming capability, high efficiency, and advanced control system contribute to faster and more effective CIP processes, reducing downtime and improving overall productivity.

2.Compliance with Industry Standards: The stainless steel self priming pump meets and exceeds industry standards and regulations for hygienic equipment and CIP processes. This compliance ensures that the pump is suitable for use in highly regulated industries, providing peace of mind and confidence in its performance and reliability.

3.Reduced Water and Chemical Consumption: The advanced control system and optimized pump design contribute to reduced water and chemical consumption during CIP processes. This advantage not only saves costs but also minimizes the environmental impact by conserving resources and reducing waste generation.