Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The sanitary threaded level gauge valve is a critical component in hygienic processes, providing accurate and reliable measurement of fluid levels. This valve offers exceptional precision and durability, allowing operators to monitor and control fluid levels with ease.

Product parameter

| Standard | SMS,3A | |

| Material Contact Parts | SS304/SS316L(1.4301/1.4404 | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Size | 1/4”, 3/8”, 1/2”, 3/4” | |

| Glass Size | Suitable for OD 19mm Glass | |

| Connection | Butt Weld, TC Ends, Male Thread, Union, Flange | |

| Seal Material | Silicone,EPDM,FKM,Buna, PTFE. All seals material comply with FDA21CFR117.2600 | |

| Working Pressure | 6bar(87psi) | |

| Max. Pressure | 10bar(145psi) | |

| Temperature Range | 14 ~248°F(-10 ~ +120℃) | |

| External Surface Treatment | Ra32~64uin(0.8~1.6um) | |

| Internal Surface Treatment | Ra16~32uin(0.4~0.6um) | |

| Power | Manual | |

| Function | Arranged in The Tank Body to Observe The Liquid | |

| Application | Beer, beverage, dairy, food,fruit juice, pharmacy, biological, Cosmetic, Chemical, etc | |

| Customized support | OEM, ODM, OBM | |

Our sanitary threaded level gauge valve is specifically designed to meet the demanding requirements of hygienic industries. It provides accurate and real-time measurement of fluid levels, enabling operators to monitor and control the process effectively. This valve is widely used in applications where precise level measurement is critical for ensuring product quality, preventing overflows, and optimizing process efficiency.

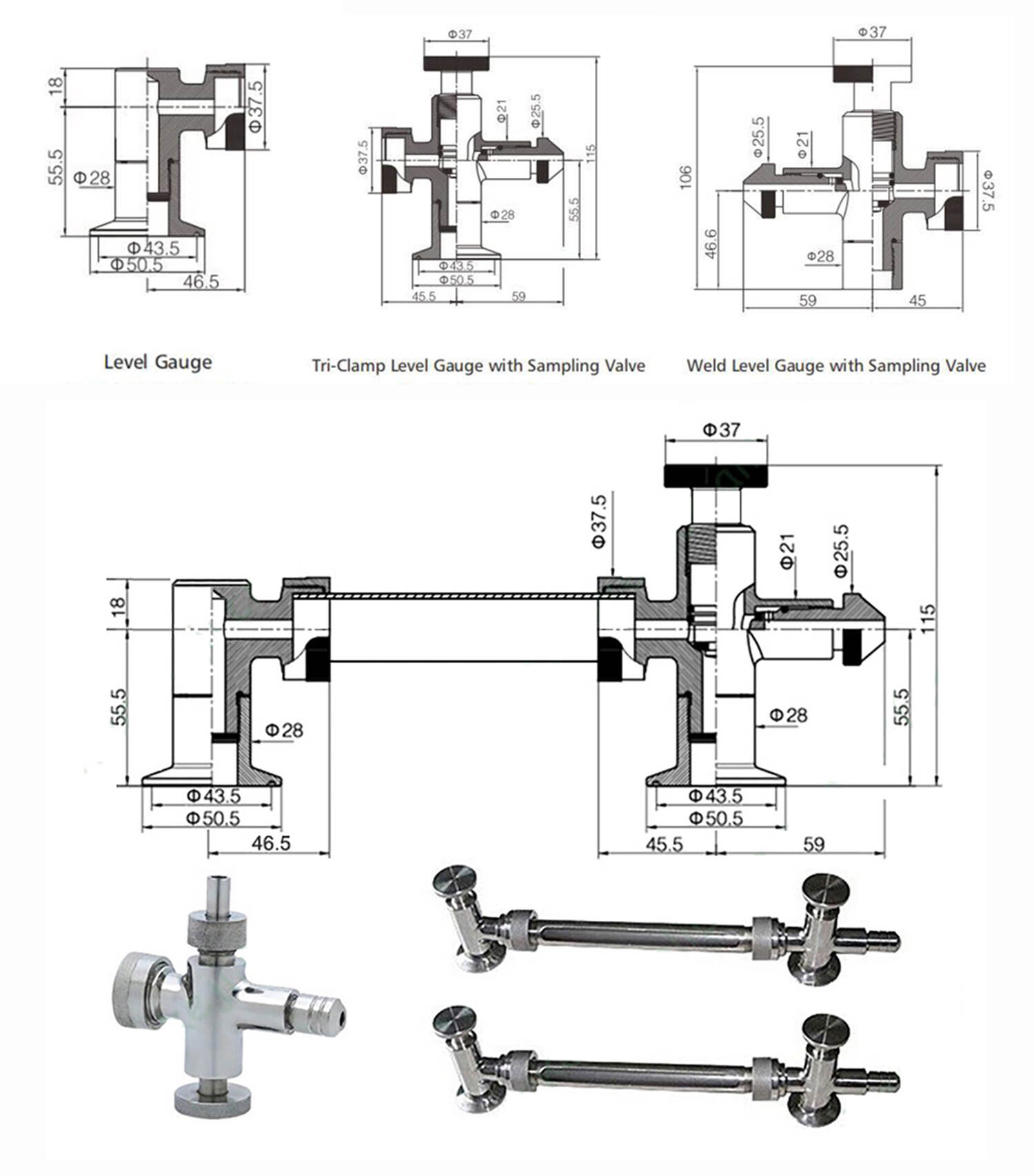

Product drawing

Product Features

Application scenario

Product Advantages

1.Process Optimization: The sanitary threaded level gauge valve enables precise level measurement, allowing for accurate process control and optimization. Operators can maintain optimal fluid levels, preventing overflows or underfills, and ensuring efficient process performance.

2.Quality Control: With accurate level measurement, operators can monitor and control the process to ensure consistent product quality. The valve helps in preventing product variations due to incorrect fluid levels, contributing to reliable and high-quality products.

3.Compliance with Hygiene Standards: The level gauge valve’s hygienic design and compatibility with cleaning and sterilization processes ensure compliance with stringent hygiene standards. It is suitable for use in industries with strict sanitary requirements, such as food and beverage, pharmaceutical, and biotechnology.