Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

The stainless steel one section plate heat exchanger is crafted with the utmost precision from premium-grade stainless steel, and it boasts unrivaled durability, exceptional resistance to corrosion, and remarkable thermal conductivity. Its sleek and compact design not only optimizes space utilization but also enables effortless integration into a myriad of industrial applications, ranging from sophisticated HVAC systems to intricate food processing and chemical manufacturing processes.

Product parameter

| Commodity | Plate Type Heat Exchanger | |

| Type of Plate Type Heat Exchanger |

Detachable Plate Heat Exchanger (also known as plate heat exchanger with sealing gasket) |

|

| Welded Plate Heat Exchanger | ||

| Spiral Plate Heat Exchanger | ||

|

Plate Coil Heat Exchanger (also known as honeycomb heat exchanger) |

||

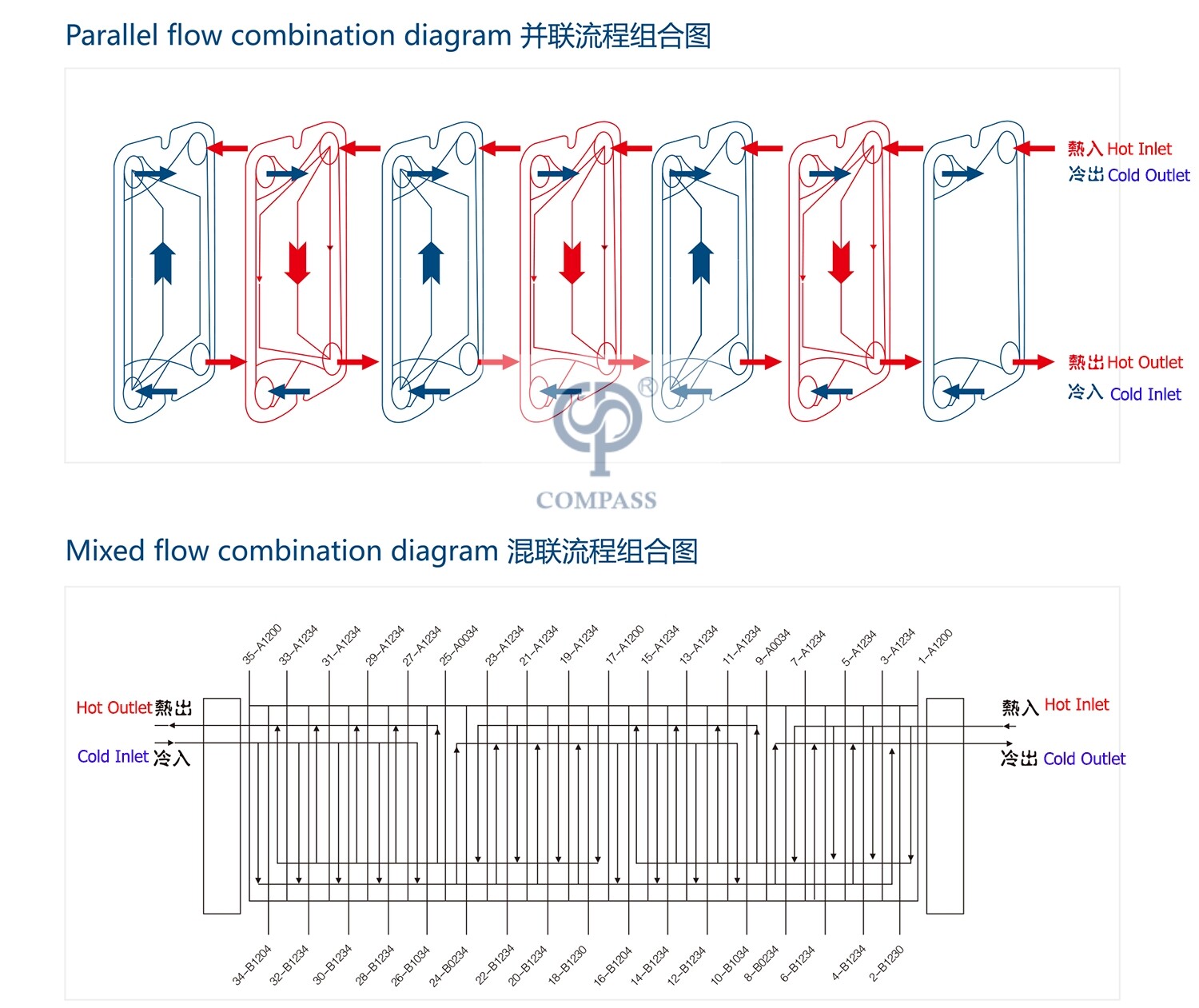

| Process Combination Form | Single Process, Multi Process, Mixed Process | |

| Material Contact Parts | SS304(1.4301)/SS316L (1.4404) | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Sealing Material | NBR,EPDM,Silicone,FKM | All material comply with FDA21CFR117.2600 |

| Flow | 0.1-1000m³/h | |

| Exchanger Type | Heating,Cooling,Evaporation,Sterilization and Disinfection | |

| One Plate Exchanger Area |

0.02m²,0.04m²,0.06m²,0.08m²,0.12m²,0.13Bm²,0.15m²,0.22m², 0.24m²,0.32m²,0.4m²,0.65m²,0.75m²,0.85m²,1.54m²,1.8m² |

|

| Plate Thickness | 0.7-1.0mm | |

| Connection | Union,Tri-clamp, Flange | |

| Max. Pressure | 10bar (145psi) | |

| Workingl Pressure | 0-6bar (0-87psi) | |

| Working Temperature | 14 ~ 302°F (-10ºC~+150 ºC) | |

| Sterilization Temperature | 302°F (150°C)≤30min | |

Feature of Plate Heat Exchanger:

Offer Large High Heat Transfer Surface Area: The arrangement of plates within the plate heat exchanger is meticulously engineered to optimize the heat transfer process, ensuring an expansive surface area for maximum thermal exchange between hot and cold fluids. This strategic configuration enables the efficient transfer of heat energy, facilitating rapid and precise temperature adjustments.

High-quality and Durable Material Ensures Long Service Life: The plate heat exchanger, renowned for its impeccable craftsmanship and utilization of premium-grade stainless steel, boasts an extraordinary lifespan, ensuring unwavering performance and reliability throughout its service life.

Premium Stainless Steel Material Makes Good Corrosion Resistance: Crafted from the finest-grade stainless steel renowned for its exceptional corrosion resistance and unparalleled durability. This superior construction material not only safeguards the heat exchanger against the ravages of corrosive elements but also ensures its longevity and resilience in the face of demanding operating conditions.

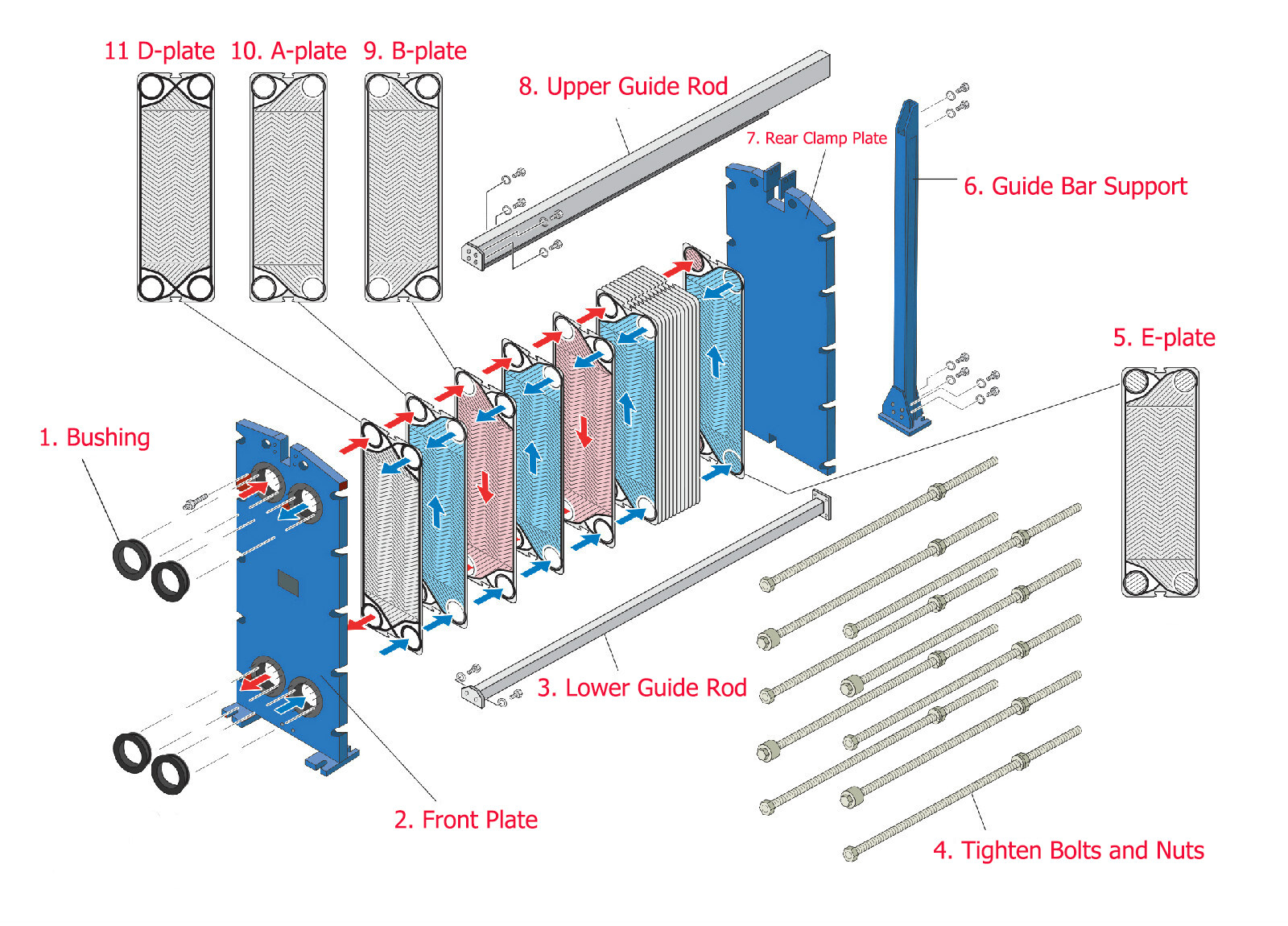

Special Design Allows for Easy Maintenance: The ingenious design of the plate heat exchanger not only ensures optimal heat transfer but also prioritizes ease of maintenance. With a user-centric approach, this heat exchanger is thoughtfully engineered to provide effortless access for cleaning the plates when necessary, streamlining the maintenance process and minimizing downtime.

Product drawing

Advantages of Plate Heat Exchanger:

High Thermal Conductivity Optimizes Overall Performance of Plate Heat Exchanger: The utilization of stainless steel in the construction of the heat exchanger is a testament to its exceptional thermal conductivity, which plays a pivotal role in facilitating efficient heat transfer between the two fluids. This remarkable property of stainless steel enables the plate heat exchanger to optimize its overall performance, resulting in reduced energy consumption and accelerated heat exchange processes.

Strong Temperature and Pressure Resistance Fits for Various Application: The versatility of stainless steel one section plate heat exchangers is truly remarkable, as they exhibit exceptional adaptability to a diverse range of temperature and pressure conditions. This inherent flexibility makes them an ideal choice for a myriad of applications across industrial, commercial, and residential sectors.

Application scenario