Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

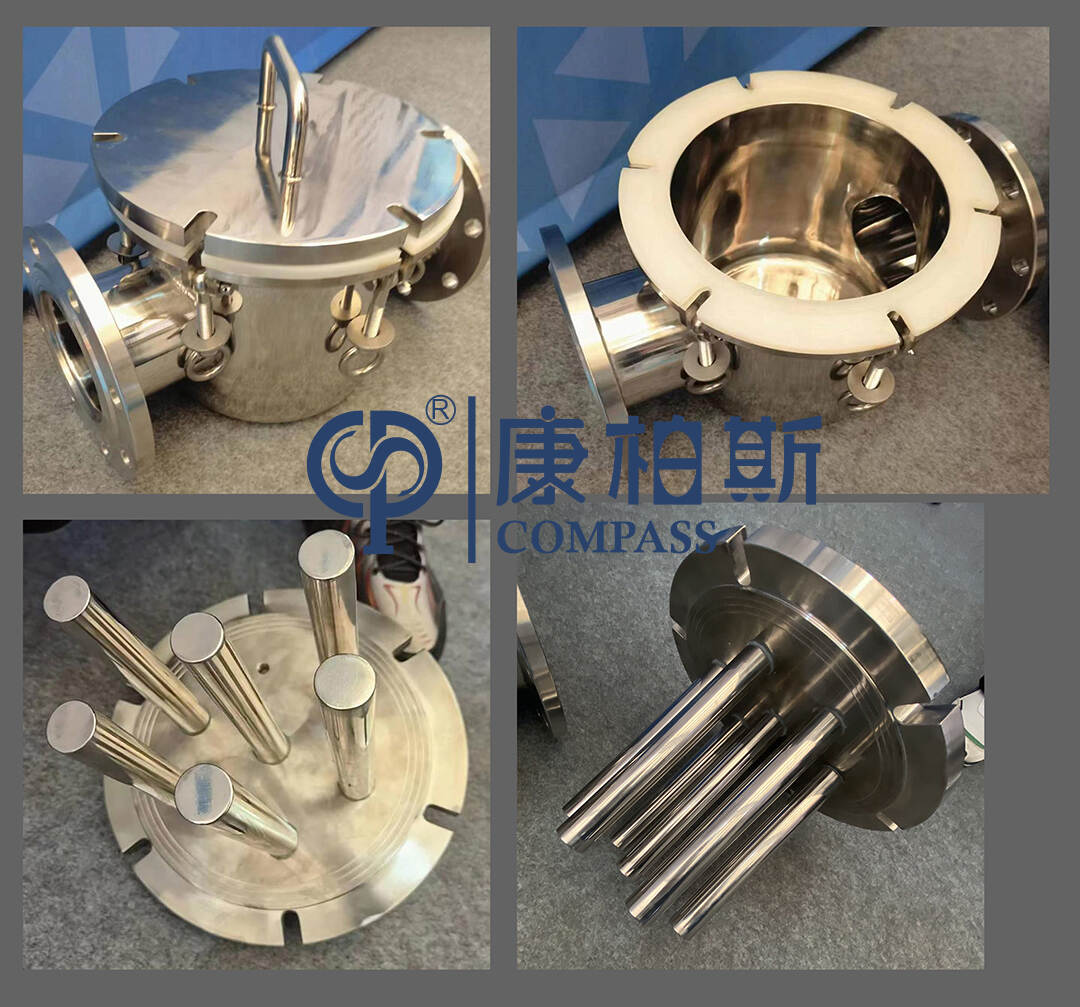

The magnetic trap uses state-of-the-art magnet technology, this advanced device effortlessly attracts and captures even the most minuscule ferrous particles, safeguarding downstream equipment and upholding the highest standards of product quality. Its sleek and compact design, coupled with seamless installation, makes the Magnetic Trap an unparalleled choice for industries seeking an elevated level of efficiency and reliability in maintaining the purity and integrity of fluids and gases throughout their industrial processes.

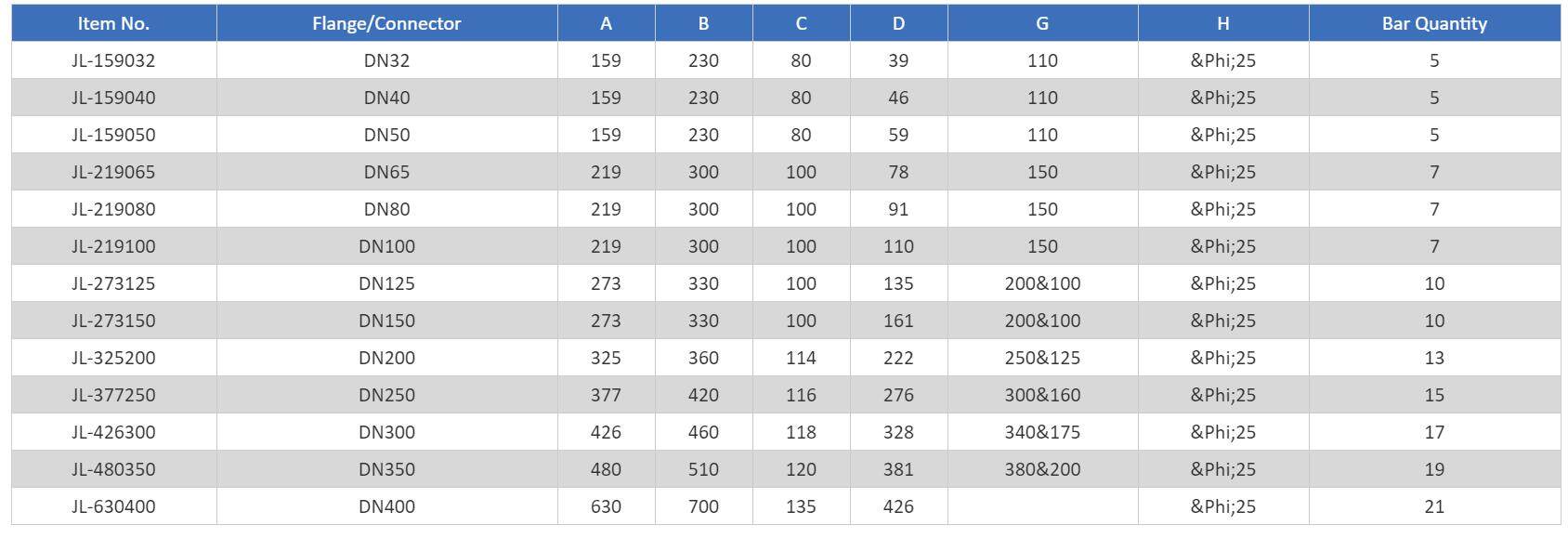

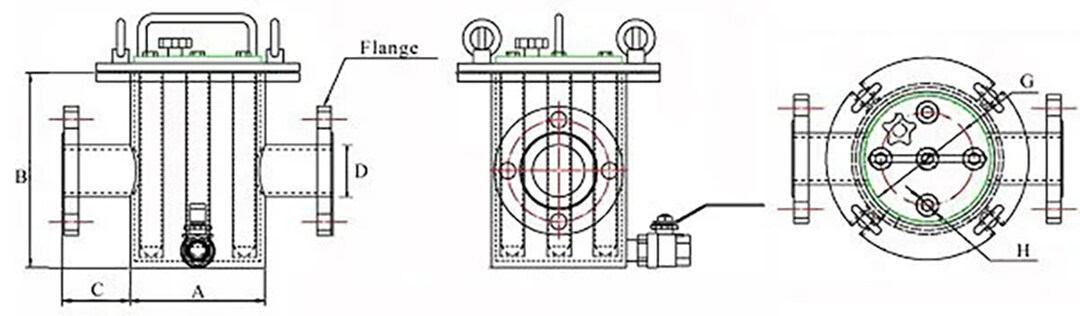

Product parameter

| Commodity | Magnetic Trap | |

| Material Contact Parts | SS304(1.4301),SS316 (1.4401) | Provided with material inspection report |

| Material Non-contact Parts | SS304(1.4301) | |

| Connection Size | 1-1/2"-20", DN32-DN500, customized size is welcome | |

| Connection | Ferrule ends, flange ends, union ends, butt-weld ends, thread ends | |

| Magnetic Gauss | 10000gauss ,12000gauss,13000gauss,15000gauss | |

| Magnetization Direction | Axial, Radial, Multi-Poles Magnetization | |

| Surface Polished | Mirror Polished, matte polished, sand blast | |

| Temperature | Standard working temperature≤80ºC, and maximum working temperature can reach 350ºC as required | |

| Application | Food, plastic, chemical, rubber, pharmaceutical, ceramic, environmental protection, pigment, fuel and other industries | |

Feature of Magnetic Trap:

Efficiently Remove Ferrous Contaminants: Magnetic traps epitomize unparalleled efficiency when it comes to eliminating ferrous contaminants from process streams, guaranteeing the utmost purity of liquids or gases by eradicating any trace of magnetic impurities. With their exceptional efficacy, these advanced devices set a new standard for precision and reliability, ensuring that industrial processes remain untainted by even the most minute magnetic particles.

Strong and Powerful Function to Attract Any Size of Contaminants: The magnetic traps are ingeniously engineered with robust and formidable magnets, renowned for their exceptional strength and power. These magnets possess the remarkable ability to attract and ensnare a wide spectrum of ferrous particles, ranging from minuscule micron-sized particles to more substantial contaminants.

Versatile Functions Ensure Wide Range of Application: The magnetic traps find extensive utility across diverse industries and applications, spanning the realms of food and beverage processing, pharmaceutical production, chemical manufacturing, water treatment, oil and gas refining, and beyond. Their versatility knows no bounds as they seamlessly integrate into various processes, safeguarding the purity and integrity of fluids in countless industrial settings.

Advantages of Magnetic Trap

Easy to Install and Maintain: Magnetic traps exemplify a remarkable ease of installation and demand minimal maintenance. Their seamless integration into pre-existing pipelines or systems is effortlessly accomplished, showcasing their adaptability and versatility.

Compact Design Requires Minimal Space Requirement: They embody a sleek and compact design, facilitating effortless integration into pre-existing systems. Their ingeniously engineered structure boasts a remarkably small footprint, guaranteeing minimal space requirements.

Environmental Friendly Remove Contamination: Magnetic traps present a sustainable and eco-conscious approach to eliminating contaminants from fluids. These innovative devices operate without the need for consumables or chemicals, minimizing environmental impact and reducing waste generation.

Wide Range of Customized Options for Magnetic Traps: They offer a remarkable level of customization, allowing them to be tailored precisely to meet specific requirements dictated by varying operating pressures, flow rates, and temperature ranges. This adaptability extends to encompass an array of customizable options, including diverse sizes, configurations, and magnet strengths, meticulously designed to cater to the unique demands of different applications.